Reliable Steel Blanking

FEWER STEPS WITH BLANKING

As freight, material, and labor costs continue to rise, you’re looking for better solutions. Get just the steel you need when you collaborate with us on first operation blanking. And save time, money, and space.

WHAT WE DO

Another option for starting parts.

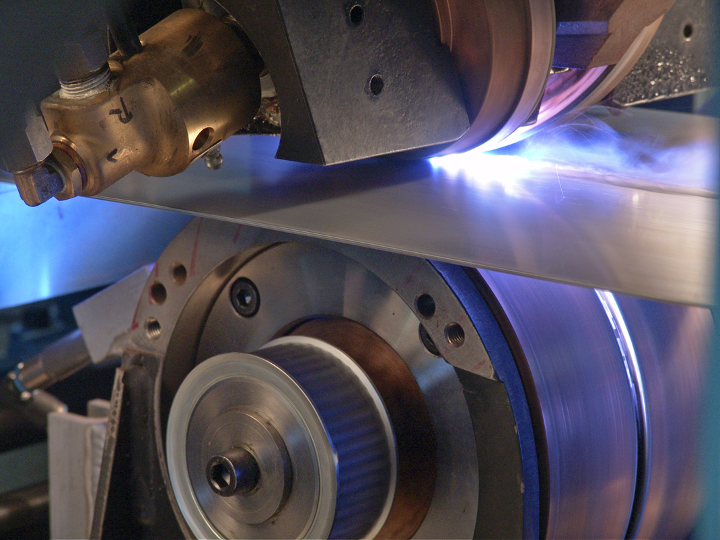

Blanking is the process of cutting out a flat, geometric shape, or blank, by feeding a coil into a press and die, to save you steps and materials on your manufacturing floor. We coil-feed our blanking lines so they run at optimal speeds and produce multiple blanks per press cycle.

END USES

Made with less waste. Made better.

Auto, truck, and consumer goods manufacturers have discovered the benefits of outsourcing the first step in parts production to us for speed and efficiency. Some products made from Worthington blanks include:

- Automotive & truck frame components

- Automotive & truck wheels

- Lawn mower decks

- Oil pan & automotive drive train parts

- Propane tanks & fire extinguishers

Full Capabilities

Check out our wide-ranging capabilities.

Collaborate with us to create the exact steel you need. We have the expertise, experience, and capacity to make your process even more efficient by adding:

- Pickling, skin pass temper rolling

- Dry film lubricant

- Slitting, oscillate slitting

- Cold rolling, one-pass rolling, temper rolling

- Hydrogen annealing

- Cut-to-length sheets

- Galvanizing, galvalume, acrylic

Explore our wide range of blanking services and partners.

Get The Detail

Your first step in producing a high-quality finished part.

What to do with your “leftover steel” is always a challenge. Deliver more value-added material with blanking from Worthington Steel. Ask us how we can bring you even greater efficiency.

HELPFUL RESOURCES

Customers who use our blanking services can decrease scrap rates and shipping costs/blank.