Impact Story

Advancing Lightweighting Technology

Worthington Steel joint venture TWB Company is poised to bring its lightweighting technology to even more cars.

TWB is the largest supplier of tailor welded blanks in North America with years of experience producing millions of welded blanks. Going forward, TWB’s new ablation licensing agreement will allow TWB to extend its mass scale into the fastest-growing part segment of the industry – welding of hot-formed tailored blanks. While today most cars are made with one or two tailor welded blanks, this agreement allows for more applications, including pillars, rails, cross-car beams and door rings, which will significantly increase tailored parts per vehicle.

Ivan Meltzer, TWB President

Ablation is an accepted industry process that allows us to weld aluminum-coated advanced high-strength steels. This technology greatly enhances strength, improves crash performance and reduces the weight of automotive applications. It’s no surprise hot-formed tailored blanks utilizing ablation is one of the fastest growing segments in the tailored blank market.

Expanding Capabilities

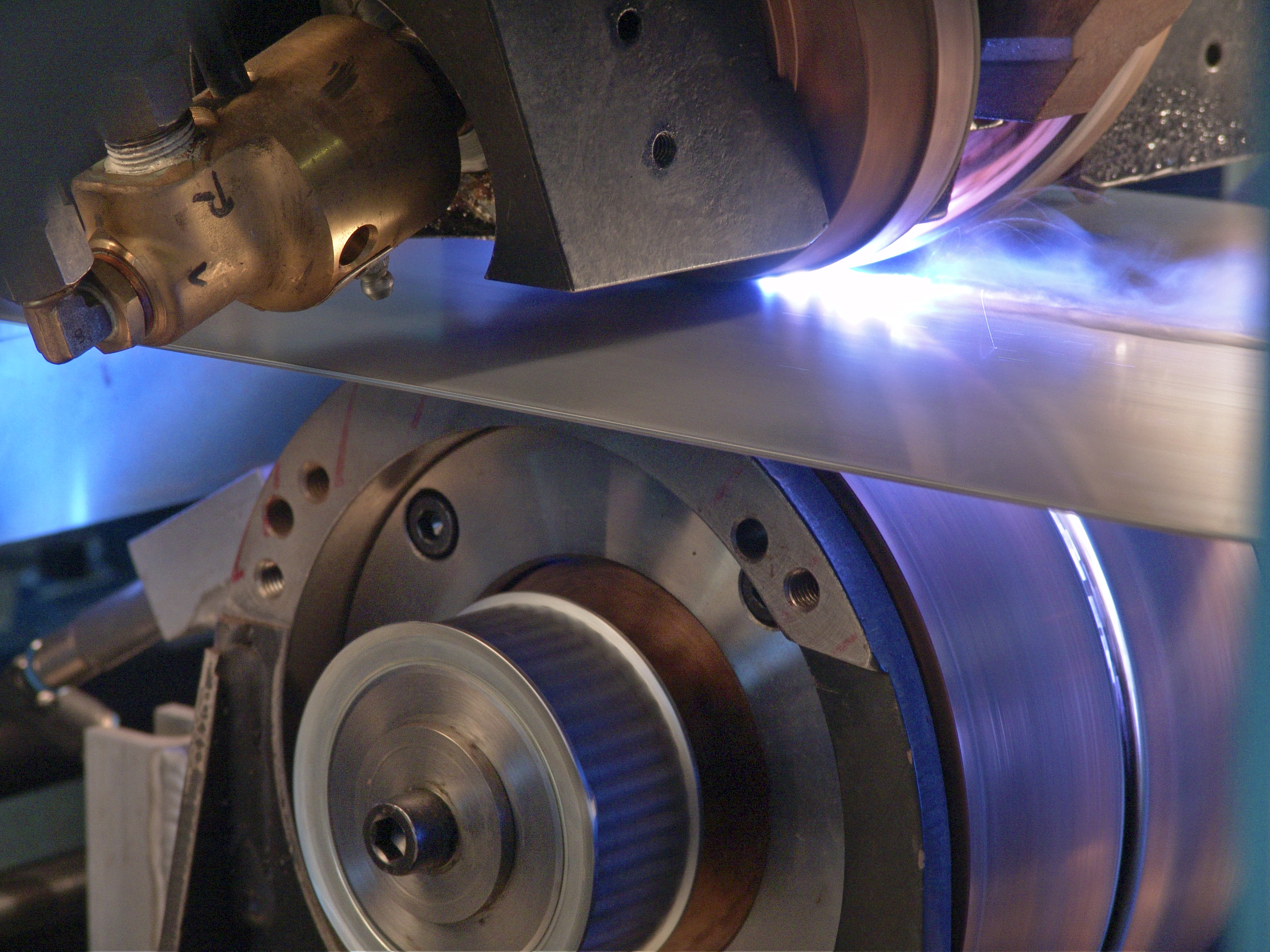

Ablation in the production of tailor welded blanks uses steel protected with an aluminum silicon coating. This coating must be removed from the weld edge of tailored blanks before they are welded together to ensure better weld quality, reduce the risk of defects and enhance corrosion resistance.

A new licensing agreement with ArcelorMittal Tailored Blanks to use its patented ablation technology means TWB can expand its hot formed tailored blanking capabilities.

Tailor Welded Blanks

- Optimize crash performance through the use of high-strength materials that absorb impact in highly stressed areas.

- Make the vehicle body lighter, which results in a reduction in fuel consumption and supports the automotive industry in achieving CO2 targets.

- Reduce production costs, since high-quality and expensive materials are used only where they are necessary, and welding different materials with different thicknesses into a single blank can happen first, and then it can be stamped as one complete part.

- Lower investment costs through fewer parts in tooling and assembly lines.

- Improve corrosion properties by eliminating overlapping joints.

Marketplace Growth

This agreement creates an opportunity to grow the marketplace for tailor welded blanks, because expanding the market beyond a single supplier gives original equipment manufacturers (OEMs) more confidence to buy them. With multiple suppliers in the mix, OEMs can count on resilience and flexibility in their supply chains, quality manufacturing and product innovation.

More applications and a larger marketplace means an increase in the tailor welded blank content on a vehicle. Why does that matter? Tailored blanks—steel or aluminum sheets made by welding together individual sheets that vary in thickness, strength and coating—allow automotive engineers and manufacturers to create vehicle parts that are lighter, stronger, safer and easier to manufacture. Tailored blanks reduce the weight of a car while increasing its strength by designing the right material in the best place.

This new licensing, which allows TWB to expand and serve more customers in more regions, includes creating additional capacity at its facility in Monroe, Michigan, with a fully automated ablation line.