Impact Story

At Worthington Steel, safety isn’t just a requirement — it’s a commitment. Across our facilities, teams continually look for ways to reduce strain, improve the work environment and help ensure everyone ends each shift feeling their best. That commitment came to life at our Taylor, Michigan, facility, where employees embraced a renewed focus on ergonomics and reimagined how everyday tasks can be done more safely and efficiently.

Seeing Opportunities in Everyday Tasks

Certain physical motions, like lifting, twisting, reaching and other repetitive movements, can add up over time. When our Delta, Ohio, facility piloted the VelocityEHS HumanTech ergonomic assessment tool in 2023, leaders there saw an opportunity to better understand where those stresses were occurring and how to reduce them.

“I was looking for an opportunity like this, so I jumped on it,” said Patrick Turner, senior safety and health coordinator.

After helping launch the program in Delta, Turner later moved into a full-time safety role at our Taylor facility, where he partnered with production trainer Johnathan Moore-Schultz to bring the same approach to employees in Michigan.

“I fell in love with the program and what it can bring not only to one facility, but to Worthington Steel as a whole,” Moore-Schultz said. “Trying to improve ergonomics and make tasks safer is good for everyone.”

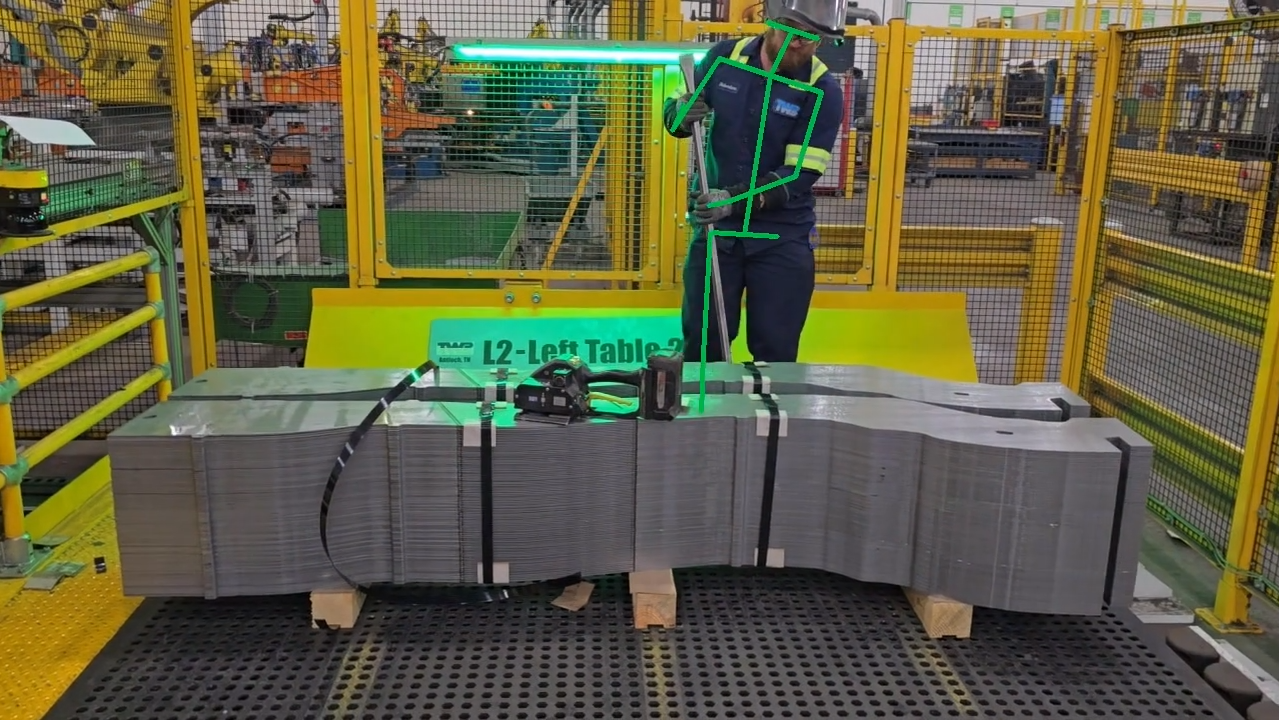

Click the play button to watch the program in action.

How the Program Works

The HumanTech tool analyzes short videos of employees performing their tasks and generates a score that highlights ergonomic risk areas. That score becomes a starting point for teams to identify improvements that make the work noticeably easier and safer.

Taylor employees quickly took ownership of the process.

“People are now coming to us asking to use the tool,” Turner said. “They want to know if there’s a better way to get a job done. Most of the time, there absolutely is.”

Results from an ergonomics body assessment performed in the facility.

Small Changes, Big Impact

In just two years, the Taylor team has completed improvements on 72 tasks, generating 372 improvement points, nearly double this year’s goal of 200.

Many improvements were straightforward but meaningful. Examples include:

- Reducing bending and lifting: In several areas, employees previously had to pick items up from the floor and lift them to worktables. By adding carts and repositioning materials at waist height, teams eliminated repeated bending motions and reduced strain on backs and legs.

- Reworking heavy equipment handling: The team identified a 115-pound banding spool that previously had to be lifted into a dispenser. To combat this, they added a foot pump adjustable cart to raise the dispenser without bending and installed stabilizing brackets so the spool can be slid into the cart more easily, reducing overall strain.

- Optimizing repetitive motions: Simple changes in workstation layout — like repositioning tools within easier reach — reduced twisting, stretching and long-term wear on joints.

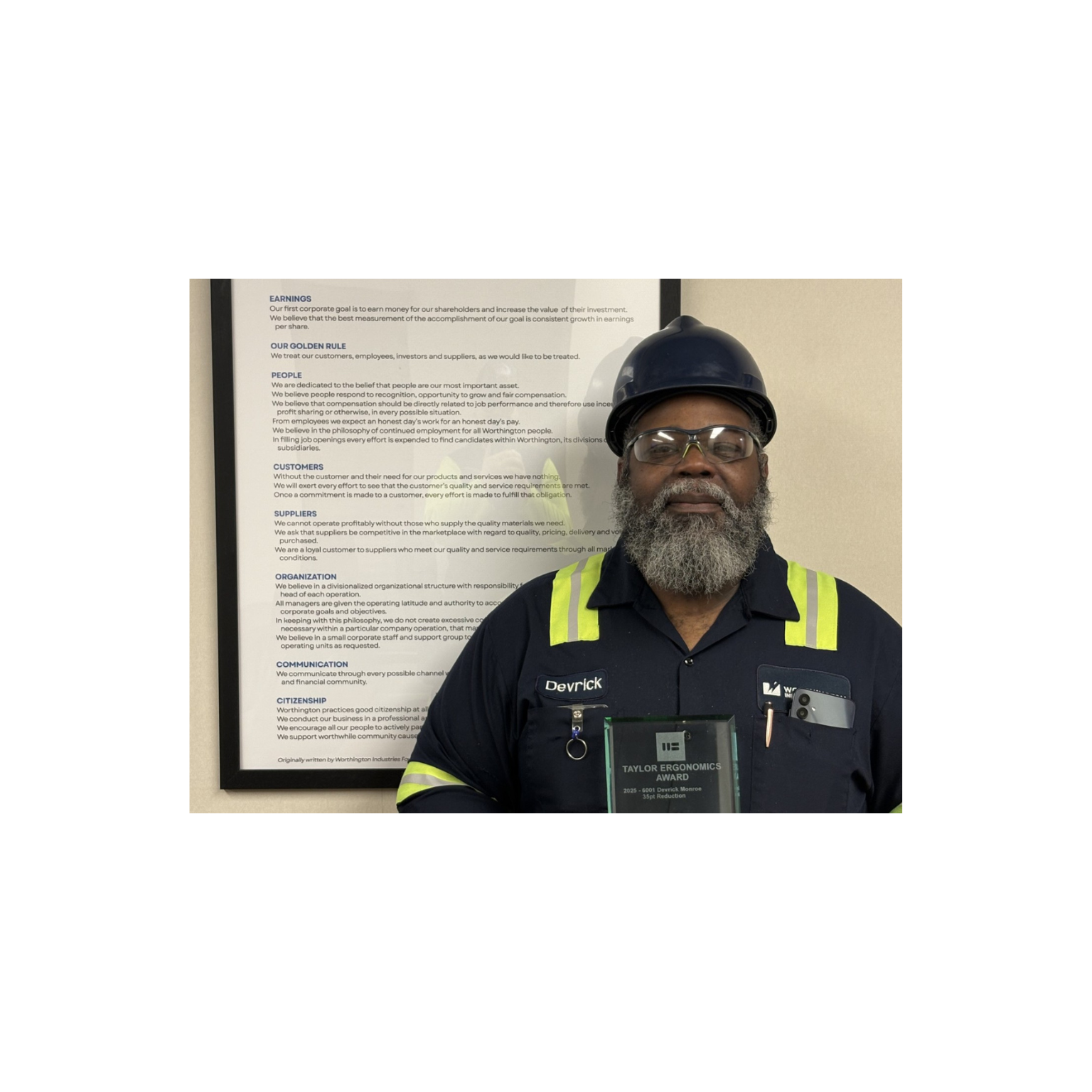

To recognize the teams behind this momentum, the facility created an ergonomics award that highlights employees who contribute the most improvement points each year. Winners have their names engraved on a shop-floor trophy and receive a celebratory lunch.

“The foundation we built touches on Our Philosophy,” Moore-Schultz said. “Continuous improvement allows us to make a positive impact on both current and future employees.”

Devrick Monroe, operator and "Taylor Ergonomics Award" winner, pictured left.

Patrick Turner, senior safety & health coordinator

People are now coming to us asking to use the tool. They want to know if there’s a better way to get a job done. Most of the time, there absolutely is.”

A Culture That Makes Safety Possible

Turner and Moore-Schultz agree that the success of the program reflects Worthington Steel’s strong culture of safety and trust. Technology provided helpful insights, but the real progress came from daily teamwork and open communication.

“At the end of the day, we want these jobs to be the safest and easiest they can possibly be,” Moore-Schultz said. “That only happens when employees speak up and partner with us. Their buy-in is what makes this work.”

This proactive approach aligns closely with Worthington Steel’s operating approach: identify risks early, involve people closest to the work and prevent issues before they happen.

Click the play button to watch how our teams use HumanTech to analyze different tasks.

Looking Ahead

With this year’s goal for improvement points already surpassed, the Taylor team is continuing to evaluate earlier projects and expand ergonomic improvements to new areas of the facility. And their success has helped pave the way for broader rollout across Worthington Steel.

“Now we’re able to revisit the first projects we did,” Turner said. “Are we still on track? Are we using everything the way we intended? If not, why?”

Taylor’s progress shows what’s possible when people, tools and culture come together with a shared purpose. As the HumanTech initiative expands across the company, early adopters like Taylor are demonstrating the long-term benefits — safer tasks, smarter processes and a workplace built around the well-being of our people.

Turner and Moore-Schultz pictured left.